pisau gergaji berlian untuk memotong beton bertulang

sang berlian melihat kekuatan bilah: pemotongan cepat dengan umur panjang, menghemat energi dan batu. pemotongan cepat dengan umur panjang menghemat energi dalam daya dan batu

merek:

SANGitem no.:

SG-NEW-CONCRETE-111pembayaran:

TT100%,Western Union,Paypal,Money Gram,etcasal produk:

Fujian Chinapelabuhan pengiriman:

Xiamen or Guangzhou Portmemimpin waktu:

7~14 days after payment recievedMOQ:

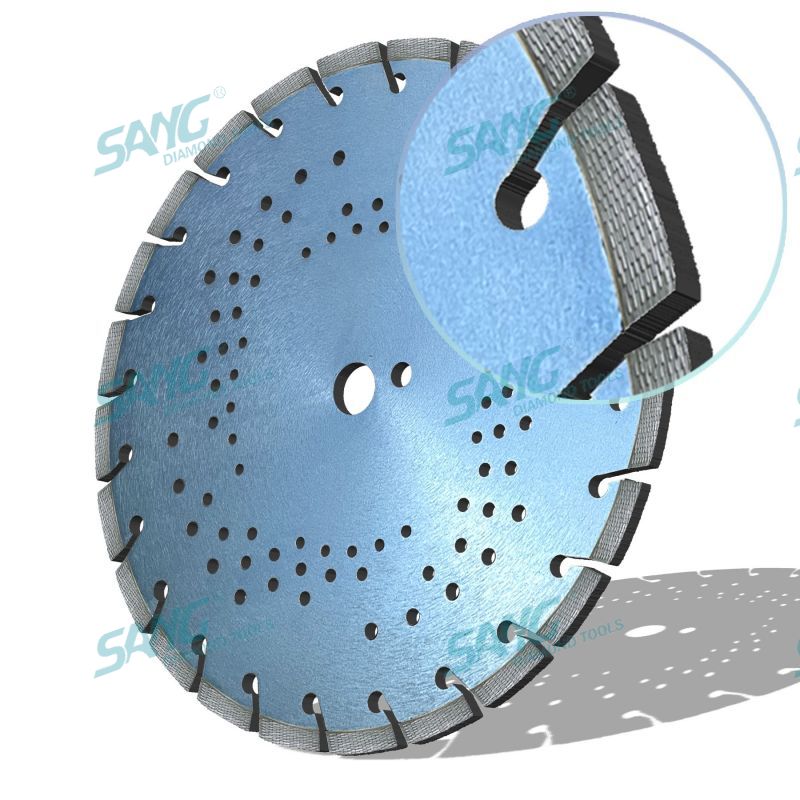

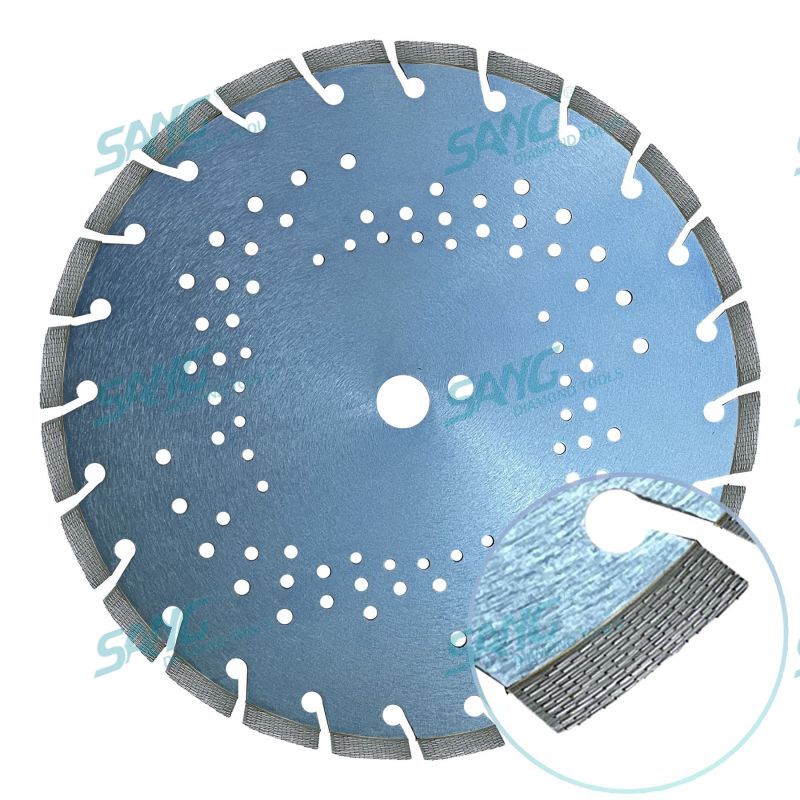

5pcsPisau Gergaji Berlian Dilas Laser Segmen Arix Premium 16 Inci untuk Blok Bata Beton dan Batu Kering atau Basah

Segmen Arix: Arix adalah jenis teknologi segmen berlian yang meningkatkan kecepatan pemotongan, kinerja, dan masa pakai. Biasanya terdiri dari beberapa lapisan berlian yang disusun dalam pola tertentu, sehingga menawarkan peningkatan efisiensi pemotongan.

Dilas dengan laser: Segmennya dilas dengan laser ke inti bilah, memastikan ikatan yang kuat dan mengurangi risiko hilangnya segmen selama pemotongan.

Diameter 16 inci: Bilahnya memiliki diameter 16 inci, yang cocok untuk pekerjaan pemotongan yang lebih besar.

Pemotongan basah atau kering: Pisau dirancang untuk bekerja dengan metode pemotongan basah dan kering. Pemotongan basah biasanya memberikan pendinginan dan pengurangan debu yang lebih baik, sedangkan pemotongan kering menawarkan kemudahan dalam situasi tertentu.

Cocok untuk berbagai bahan: Pisau ini dirancang khusus untuk memotong beton, batu bata, balok, dan pasangan bata. Ini dirancang untuk tahan terhadap tantangan material ini dan memberikan kinerja pemotongan yang efisien.

Spesifikasi lain berdasarkan permintaan tersedia.

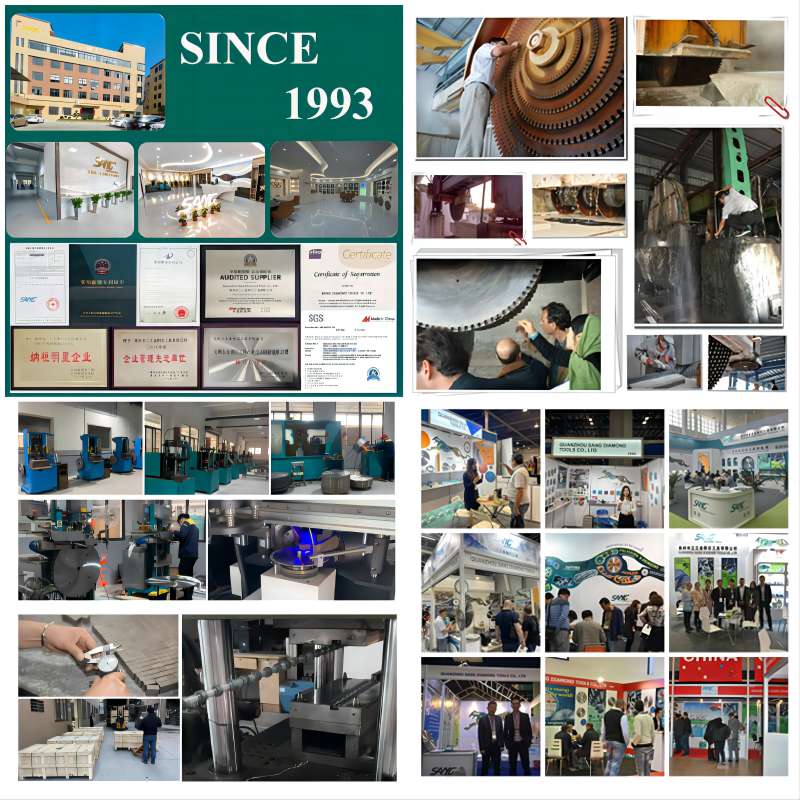

ISO9001 & Pemasok Emas

Pabrik = Kontrol Kualitas = Harga Kompetitif = Teknologi sendiri = OEM

Bagaimana proses pengelasan laser berkontribusi terhadap kekuatan dan umur panjang bilah secara keseluruhan?

The laser welding process used in diamond saw blades contributes significantly to their overall strength and longevity. Here's how:

Strong bond: Laser welding creates a strong bond between the diamond segments and the blade's core. This bond is essential because it ensures that the diamond segments remain securely attached to the blade during the cutting process. A strong bond reduces the risk of segment loss, which can lead to inefficient cutting and potential safety hazards.

Heat distribution: Laser welding allows for precise control of the heat distribution during the welding process. This control ensures that the heat is evenly distributed, preventing excessive heat buildup that could potentially damage the diamond segments or the blade's core. By maintaining appropriate temperature levels, the blade's structural integrity is preserved, enhancing its overall strength and longevity.

Enhanced durability: The strong bond achieved through laser welding enhances the blade's durability. It enables the blade to withstand the high stresses and forces encountered during cutting operations. This durability translates into a longer lifespan for the blade, reducing the need for frequent replacements and saving costs in the long run.

Reduced vibration and noise: Laser-welded diamond saw blades often exhibit reduced vibration and noise levels during cutting. The precise and strong bond between the segments and the core helps to minimize vibrations, resulting in smoother cutting operations. Reduced vibration not only improves cutting accuracy but also reduces operator fatigue and enhances user comfort.

Overall, laser welding contributes to the blade's overall strength and longevity by ensuring a strong bond, even heat distribution, enhanced durability, and reduced vibration. These factors combine to provide a reliable and long-lasting saw blade that can withstand the demanding cutting applications in concrete, bricks, blocks, and masonry.

FAQ

1.Are you a manufacturer or trading company?

We are a 31 years manufacturer.

2.How to prove your quality?

We use E6 diamond,Dipea steel wire, passed ISO9001 and SGS,strict quality control and skilled workers.

3.What should I do if the products is not suitable for the market?

Giving us the detailed report first,then we analyze the reason,try to find the solutions.

If it is our problems,we will give you new products.

4.Do you provide free samples?

Small sample is welcomed.But,usually we don't provide free samples.

5.Can you provide OEM/OEM services?

It is ok.

6. Any question about 16 Inch Premium Arix Segment Laser Welded Diamond Saw Blade for Concrete Brick Block and Masonry Dry or Wet, please kindly let me know!Thanks!

Anda dapat menghubungi kami dengan cara apa pun yang nyaman bagi Anda. kami tersedia 24/7 melalui faks, email atau telepon.